Reduced Pressure Testing of Aluminum Melts

The Importance of Gage Selection

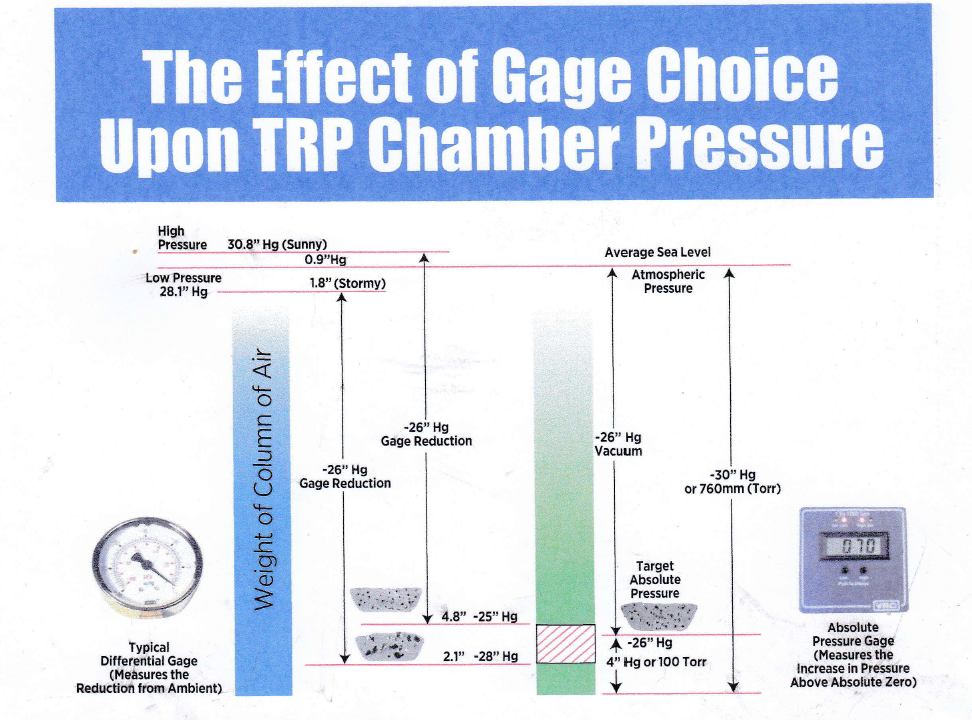

The differential gage on the left, as used on most current RPT testers, measures a change in vacuum level from the current atmospheric pressure. As may be seen from the graph of atmospheric pressure in Madison, WI below, the pressure may vary over an average range from about 30.8 inches of mercury down to about 28.1 inches when high and low pressure weather systems pass through the area. By lowering the chamber pressure by 26 in.Hg, as measured with a differential gage, the actual chamber vacuum might vary over a range as much 4.8 in.Hg to 2.1 in.Hg (or the equivalent reading measured in mmHg) above a perfect vacuum.

For accurate testing of aluminum melts, the answer is to use the absolute vacuum gage on the right, which ignores variations in the current atmospheric pressure. With this type of meter, the test chamber may be always evacuated to a constant level, which is a major controlling variable in the size of the induced porosity in Reduced Pressure samples. The resulting process control accuracy that is achieved is one of the primary benefits of using a T.R.P. Tester (True Reduced Pressure).

Typical Ranges of Atmospheric Pressure

This plot shows the daily average mean sea level pressure reported at the Dane County Regional Airport for the three year period covered. The net effect of these pressure changes can introduce significant errors to the test chamber vacuum level, as may be seen below.

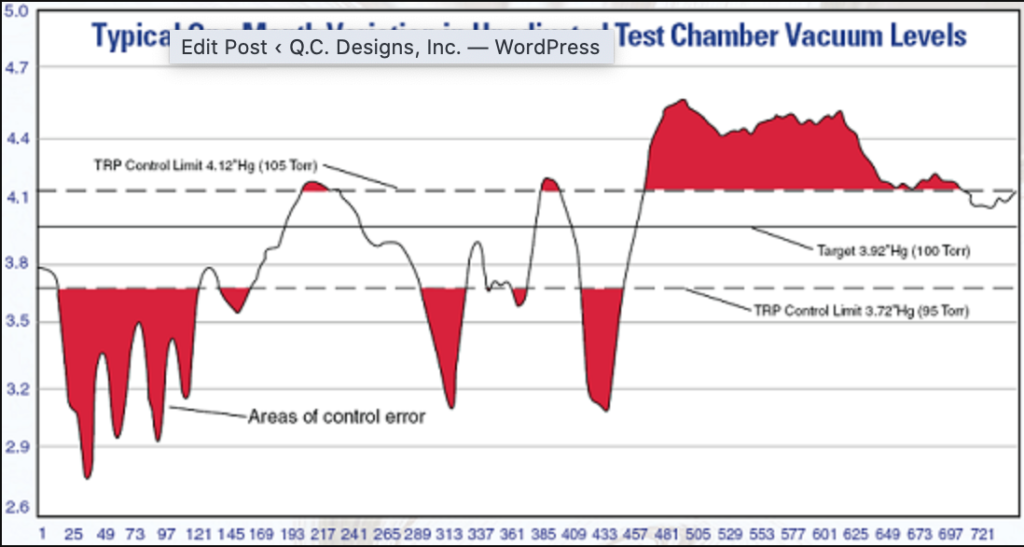

The graph shows the resulting chamber vacuum level after pulling down the vacuum to the -26″Hg gage reading. The colored areas are zones of control error and represent the amount of improvement achieved by the TRP Vacuum tester.

1http://iridl.ldeo.Columbia.edu/SOURCES/.NOAA/.NCDC/.DAILY/.STATION.cuf/.mean/.se..

Vacuum Testing of Aluminum

Vacuum Testing of Aluminum