Skim Station Dross Boss™

Description

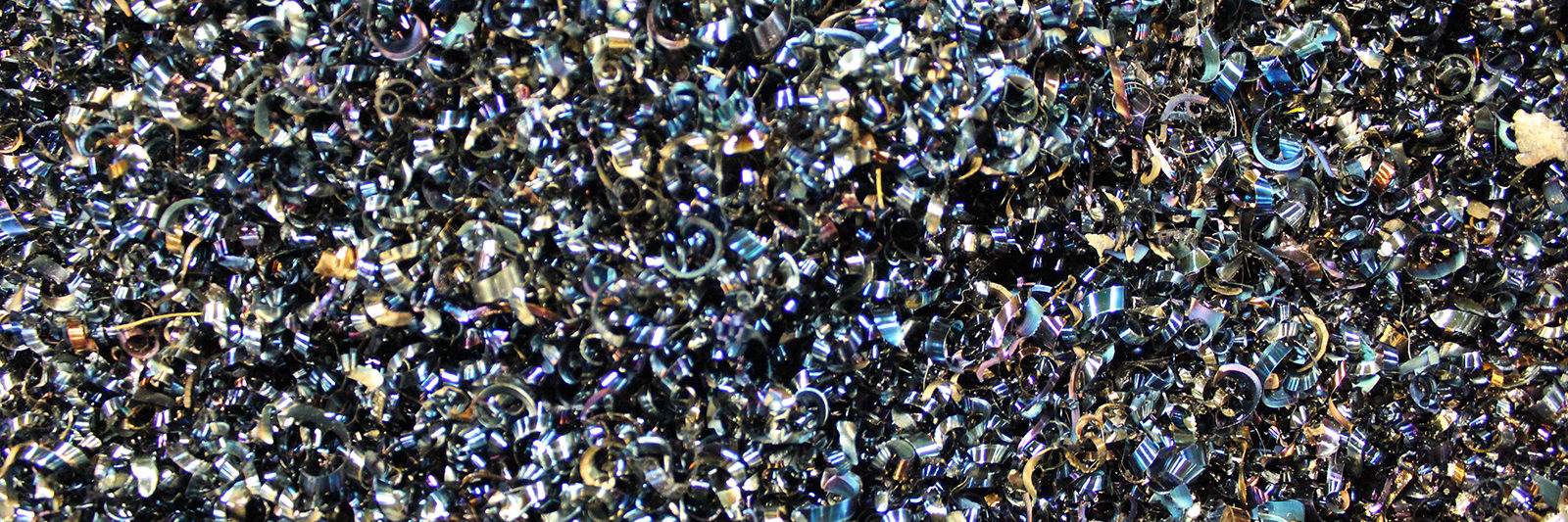

The customer is using this equipment to process drosses generated while flux injecting a 1,300 lb. volume of metal contained in a transfer ladle. The ladle treatment operation produces between 12 – 15 lb. of dross, which is then transferred to the unit Reaction Vessel located in a smoke hood. After an automatic mixing cycle is run, approximately 7 lb. of clean, 383 alloy are collected in the bottom ingot pan for return to the process stream. An average production day treats approximately 90 – 130 ladles, and recovers more than 700 lb. of metal.

Equipped with a 35 lb. nominal capacity reaction vessel and holder, complete electrical controls automation package system for the mixing and processing of hot aluminum dross.

Related Products: #200 Molten Return Dross Boss™, Automatic Dross Boss™ Buggies (60-150lb.), Barrel Units (10-60lb.), Hot Metal Return Units (30-300lb.), Portable Unit (35-60lb.), Remote Station Units 300-1000lb.), and the Skim Station Dross Boss™.

Contact us for more information.

Daniel E Groteke

dan@qcdesignsinc.com

Michael Maravich

michael@qcdesignsinc.com

810 Botham Ave., St. Joseph, MI 49085

Phone: (269) 983-6859

Fax: (269) 982-0823