Customer Report

Portable Dross Boss Processing Units

Customer

City Aluminum Foundry Co.

2505 Williams Dr.

Waterford, MI 48328-1869

Contact

Chuck Juliarr, Vice President

248-335-8785

Customer Report

Melting Practices

We pour primarily 356, 319 and 535. Our Hunter molding line has 4 Inductotherm I 300 pound resistance furnaces.

Practice Comparisons

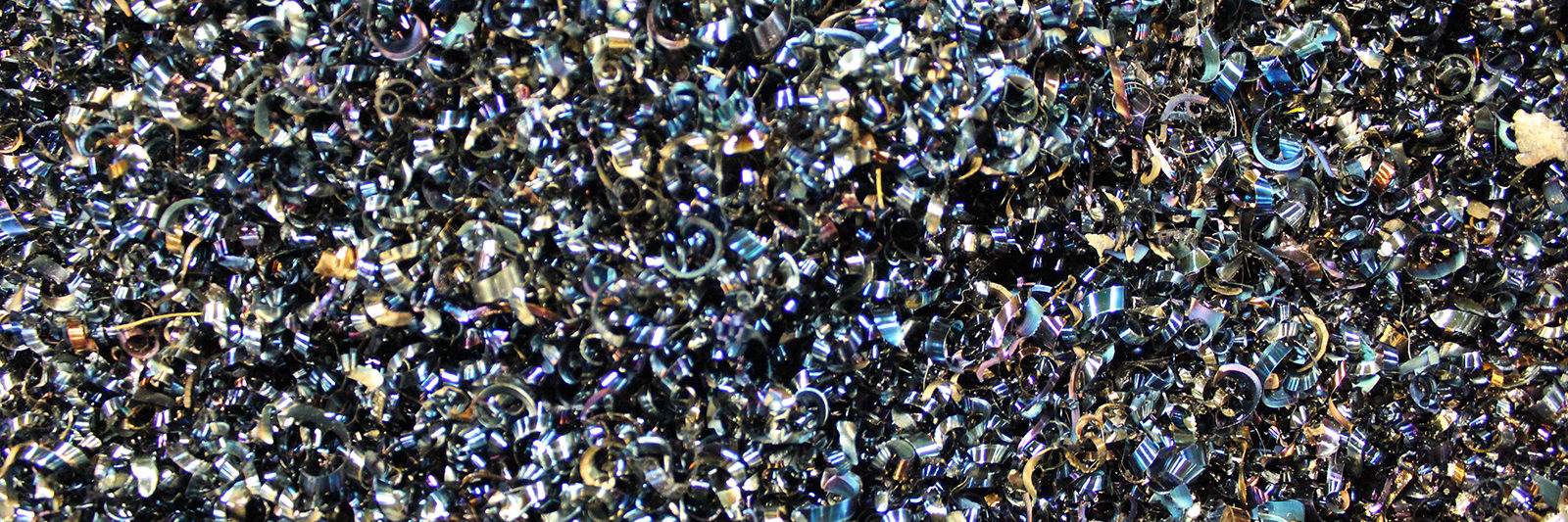

We typically get two batches from each furnace per day. We flux inject these furnaces. With a brick drossing table, we were generating around I drum of dross. weighing around 400 pounds, per day. With the DROSS BOSS TM, we generate one drum of dross every three days. The difference is in recovered aluminum. It seems as though we are saving 800 pounds of metal every three days. It has been possible to reduce our loss by very diligently having the furnace tenders massage the dross and get it to drain, but once you stop watching them, they slip back into their old ways because of the time it takes and we again have a lot of lost metal. We consistently get good recovery with the DROSS BOSS TM.

DROSS BOSS TM Practices

The basic treatment cycle identified above was followed with the heats processed through the DROSS BOSS TM, with the exception of a two ounce addition of exothennic flux stirred into the dross that had been transferred into the reaction vessel. The manual stirring operation was accomplished in less than three minutes, with the recovered metal being returned at elevated temperature to the holding furnace. No significant change in metal chemistry had occurred during processing.

Customer Savings

Using a conservative estimate of savings, the customer projected an approximate ($139/ day)* direct savings in metallics, with an additional saving in remelt energy by recharging the hot material to his melter. On that basis, their return on the capital investment was achieved in approximately three months.

*2013 prices