QCD-1 Porosity Measurement System

“This equipment makes possible a 20-second measurement of the specific gravity of RPT samples, eliminating the need to rely upon subjective visual examinations.”

— New Product Innovations – Modern Casting

Primary Features

- A premium 2,000g Balance System with a self-calibrating feature to maintain +/- 0.01g sensitivity in measurement of TRP weights.

- The Balance enables a direct transfer of the weight and density results to an adjacent computer for data retention.

- System is provided with detailed instructions for collection of TRP samples, and a conversion chart to convert alloy densities to a % Porosity in the measured sample.

Includes

- A preprogrammed electronic balance for density measurements

- Stainless steel hardware

- Porosity Chart

- Complete instructions

Description

NEW PRODUCT INNOVATIONS FROM “MODERN CASTING”

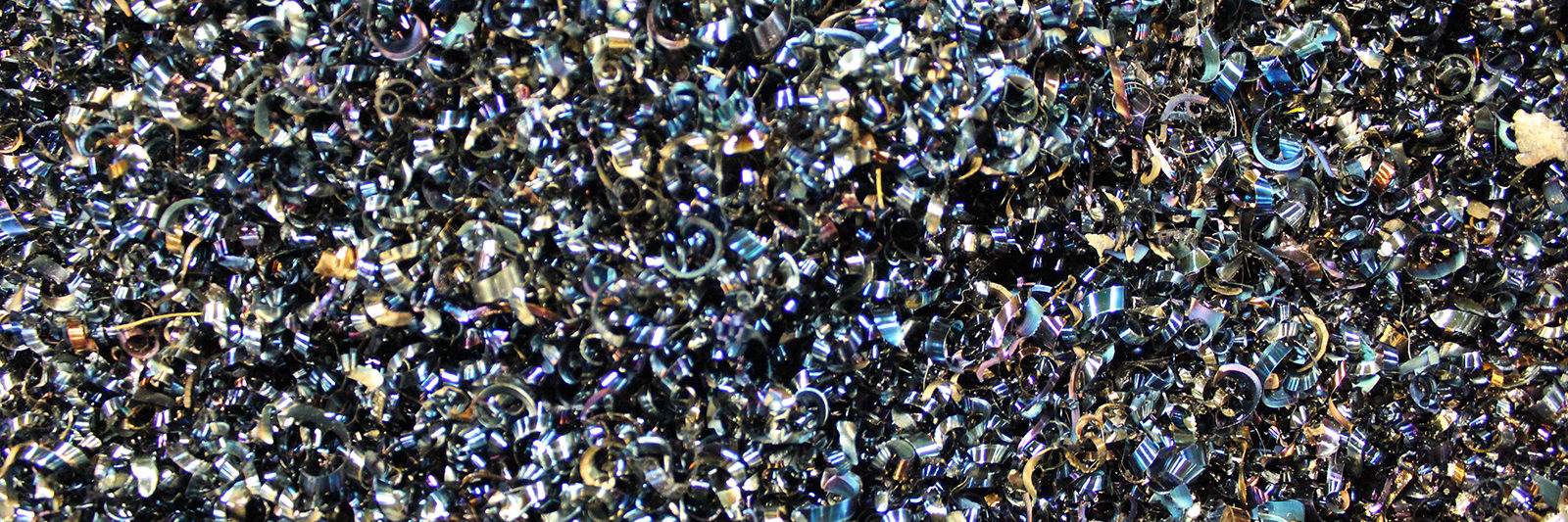

Aluminum Porosity Measurement System Foundries and die cast shops depend on the Reduced Pressure Test (RPT) to assess gas and inclusion levels in molten aluminum alloys. The test is popular because it provides a quick estimate of the levels while requiring minimal technical training and capital investment. To quantify the results, however, users must rely upon a visual comparison between the test coupon’s visible surface porosity and a reference chart. This visual comparison yields subjective results that may be affected by biases in interpretation.

To combat that subjectivity, Q.C. Designs, Inc., St. Joseph, MI, is offering equipment that will permit a 30-second measurement of the specific gravity of the RPT samples. When coupled with a second measurement of an equivalent sample solidified under atmospheric pressure, the actual “percent porosity” due to changes in the hydrogen level may be selected from a table provided with the equipment. The second measurement is required to improve the accuracy of the results. Changes in the alloy chemistry, inclusion level, metal temperature and other variables of the RPT method will change the solidification mode and shrinkage of the test coupons (all affecting the sample density and measured percent porosity).

The components of the system include a detailed test procedure, a 2000 g balance with 0.01 g sensitivity and stainless steel hardware to facilitate sample measurements in air and water. The specially programmed balance converts the measured weights in air and water to a sample density. To operate, a user inputs the individual readings by merely pushing the sample button. After the densities have been determined, the values may be downloaded to a computer with included software. Other options include the ability to measure the actual porosity levels in larger casting sections or individual castings.

Related Products: #200 Molten Return Dross Boss™, Automatic Dross Boss™ Buggies (60-150lb.), Barrel Units (10-60lb.), Hot Metal Return Units (30-300lb.), Portable Unit (35-60lb.), Remote Station Units 300-1000lb.), and the Skim Station Dross Boss™.

Contact us for more information.

Daniel E Groteke

dan@qcdesignsinc.com

Michael Maravich

michael@qcdesignsinc.com

810 Botham Ave., St. Joseph, MI 49085

Phone: (269) 983-6859

Fax: (269) 982-0823